PTFE, or Polytetrafluoroethylene, is a synthetic fluoropolymer known for its remarkable chemical resistance, high melting point, and non-stick properties. It's a thermoplastic polymer composed of carbon and fluorine atoms, with the chemical formula (C₂F₄)n. PTFE is widely recognized by its trade name Teflon® and is used in various applications, including cookware, industrial coatings, and medical devices.

Structure of PTFE:

The PTFE molecule has highly regular structure with a configuration leading to a 166 helix. It is a fully fluorinated Polymer with a linear chain of great molecular length (20,000 to 1, 00,000 Monomer units) and it has a high melt viscosity (1011 poise at 3800C). The working temperature of PTFE is –260°C to +260°C and it is insoluble in any of the commonly known solvents except certain fluorinated oils and molten alkali metals. Its chemical formula is (- CF2 –CF2-) n. PTFE is made of a carbon backbone chain, and each carbon has two fluorine atoms attached to it.

PTFE is a completely fluorinated polymer manufactured when the monomer Tetrafluoroethylene(TFE) undergoes free radical vinyl polymerization. As a monomer, TFE is made up of a pair of double bonded carbon atoms, both of which have fluorine atoms covalently bonded to them.

Thus the name “Tetra” means there are four atoms bonded to the carbons, “Fluoro” means those bonded atoms are fluorine, and Ethylene means the carbons joined by a double bond as in the classic ethylene structure. When TFE polymerises into PTFE, the carbon – to – carbon double bond becomes a single bond and a long chain of carbon atoms is formed. This chain is the polymer’s backbone.

Basic Chemical Information:

- Chemical Formula: (C₂F₄)n, where 'n' represents the number of repeating units.

- Composition: PTFE is a polymer made entirely of carbon and fluorine atoms.

- Structure: It's a linear polymer with a carbon-carbon backbone and fluorine atoms surrounding it.

- Molecular Weight: PTFE has a high molecular weight due to its long chain structure.

- Crystalline Structure: PTFE molecules pack tightly in a spiral around the carbon-carbon backbone due to the large size of fluorine atoms.

- Melting Point: PTFE's melting point is around 600 K (327 °C or 620 °F). Density: Approximately 2200 kg/m³.

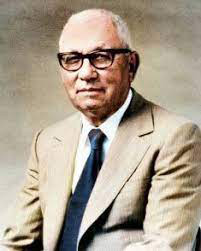

Polytetrafluoroethylene (PTFE), commonly known by the brand name Teflon®, was discovered accidentally in 1938 by Dr. Roy J. Plunkett while working at DuPont. He was experimenting with gases related to refrigerants when he found a sample of tetrafluoroethylene had spontaneously polymerized into a white, waxy solid. This discovery led to the development of one of the most versatile materials known, with applications ranging from non-stick cookware to aerospace components.

- Here's a more detailed look at the history:

Accidental Discovery: In 1938, Dr. Plunkett was working on developing a new refrigerant when he discovered PTFE. - Initial Applications:

Initially, PTFE was used in military applications during World War II, particularly in the Manhattan Project for its corrosion resistance in handling uranium hexafluoride. - Teflon® Trademark:

DuPont patented PTFE in 1945 and registered the trademark Teflon®. - Commercialization:

Commercial production of Teflon® began in 1946. - Expanding Applications:

Over time, PTFE's unique properties, including its non-stick, chemical resistance, and high-temperature stability, led to its widespread use in various industries. - Beyond Non-Stick:

While PTFE is well-known for its use in non-stick cookware, it also plays a vital role in aerospace, electronics, and industrial processes. - Filled PTFE:

In some applications, PTFE is combined with other materials, such as carbon, to enhance its mechanical strength and wear resistance

From standard sheets to custom components, we're ready to deliver quality you can rely on.

Contact Us