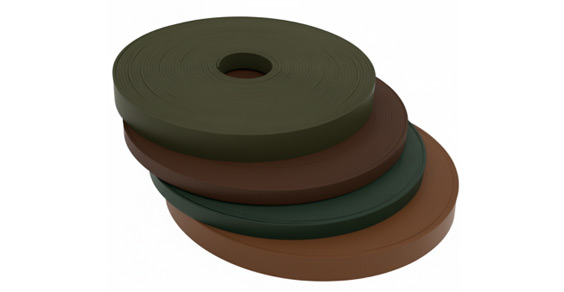

High Strength Bronze Filled PTFE Strips for Load Bearing, Wear Resistant Applications – By National Fluoromers

| Property | Value |

|---|---|

| Filler type | Bronze (typically 40% by weight) |

| Strip width | 5 mm to 300 mm (custom on request) |

| Thickness range | 0.5 mm to 10 mm |

| Operating temperature | –180°C to +260°C |

| Load bearing capacity | High – suitable for guide strips and seals |

| Surface finish | Smooth / machined / adhesive-backed (optional) |

| Color | Golden brown / bronze-gray |

Bronze-filled PTFE combines the excellent non-stick and chemical-resistant properties of PTFE with the mechanical toughness of bronze powder, making it ideal for high-pressure seals, guide strips, slideways, and bushings.

A bronze filled PTFE Strips is a flat, precision-cut strip made from PTFE resin blended with 40% (or custom %) bronze powder. The inclusion of bronze significantly enhances the compressive strength, thermal conductivity, and wear performance of PTFE while retaining its low-friction, self-lubricating surface.

These strips are ideal for sliding surfaces, dynamic seals, and wear plates that must handle repetitive motion, higher loads, or elevated temperatures.

- Enhanced wear resistance: Up to 5x more durable than virgin PTFE

- Higher load-bearing capacity: Suitable for structural and dynamic loads

- Improved thermal conductivity: Reduces heat buildup during movement

- Low friction surface: Minimizes energy loss and prevents stick-slip

- Dimensional stability: Less creep and deformation under pressure

- Customizable strip dimensions

- Operates under continuous pressure, load, and motion

- Ideal for both dry and lubricated service conditions

- Maintains sealing integrity under temperature fluctuations

- Excellent replacement for metal-backed wear strips

- Reduces maintenance downtime in high-speed machinery

- Available in roll or cut-to-size formats

- Slideways for machine tools and guides

- Bearing liners and Guide Rings

- Valve seats and dynamic seal components

- Wear pads and thrust washers

- Piston and rod support rings

- Heavy-load rail and conveyor systems

- Electrical and chemical isolation layers

- Heavy machinery & construction equipment

- Automotive & transport systems

- Marine & offshore engineering

- Steel & metal processing

- Oil & gas

- Hydraulic & pneumatic systems

- Energy & power plants

- Paper & packaging industries

- Accurate bronze/PTFE ratio for consistent mechanical performance

- In-house machining and slitting for strip customizations

- Fast lead time with small or bulk quantity options

- Export-standard material traceability and documentation

- Trusted by OEMs for durability-critical applications

- Coiled rolls or straight-cut strips

- With or without adhesive backings

- Supplied in kits or bulk cartons

- Custom sizes and shapes for CNC or manual assembly

Let us know your size, filler ratio, or application needs – and we will deliver the perfect solution for your system.

Contact Us