High Performance PTFE Rod Seals for Hydraulic & Pneumatic Applications – By National Fluoromers

| Property | Value |

|---|---|

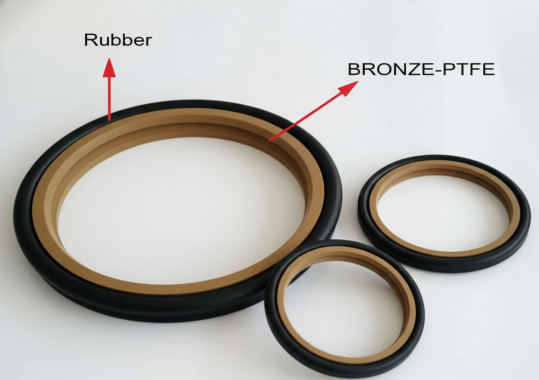

| Material | Virgin PTFE, Glass/Bronze/Carbon filled PTFE |

| Temperature range | –200°C to +260°C |

| Application type | Hydraulic & Pneumatic rod sealing |

| Design options | U-cup, Lip Seal, Step Seal, V-ring |

| Customization | Available as per drawing or OEM standard |

Crafted from high-grade virgin or filled PTFE, our rod seals ensure leak-proof performance, minimal friction, and exceptional resistance to wear—even in the most demanding industrial conditions.

A PTFE Rod Seals is a dynamic sealing element designed to seal the rod shaft of a hydraulic or pneumatic cylinder. It prevents fluid leakage from the cylinder and blocks contaminants from entering the system. The inherent properties of PTFE—such as low friction, excellent thermal stability, and chemical inertness—make these seals ideal for long-life applications across diverse industries.

Rod seals are critical in maintaining the system’s pressure balance, minimizing downtime, and enhancing machine reliability.

- Low friction & dry running capability

- Excellent chemical resistance: Suitable for all hydraulic fluids, gases, and chemicals

- Thermal stability: Operates from –200°C to +260°C

- No stick-slip motion: Ensures smooth movement at varying speeds

- Wear-resistant & long-lasting

- Available in single or double-acting designs

- Prevents leakage, contamination, and premature wear

- Operates in extreme temperatures and aggressive media

- Compatible with both high-speed and low-speed operations

- Minimizes energy loss due to low coefficient of friction

- Available in standard and custom sizes and profiles

- Reduces maintenance intervals and improves efficiency

- Hydraulic cylinders in presses and earth-moving equipment

- Pneumatic actuators in automation and robotics

- Chemical dosing and metering pumps

- Marine and offshore hydraulic systems

- Aerospace and defense cylinders

- Oil & gas pressure containment units

- Industrial and packaging machinery

- Hydraulic & Pneumatic Engineering

- Chemicals & Petrochemicals

- Oil & Gas Exploration

- Marine & Offshore Equipment

- Food & Beverage

- Pharmaceuticals & Life Sciences

- Industrial Automation

- Energy & Power Generation

- Precision-manufactured seals for extreme environments

- Custom designs to meet OEM or retrofit specifications

- FDA-compliant and anti-static materials available

- In-house engineering and quality assurance testing

- Global shipping and prompt delivery

- Seals available in standard ISO, DIN, or custom profiles

- Single seals or complete sealing kits

- Individually packed or bulk supplied

- Branding and labeling services for OEM partners

Share your size, pressure rating, or working environment – we will deliver the seal that fits perfectly.

Contact Us