The Molding Department is the first step in the PTFE processing chain. We employ hydraulic and compression molding machines with a wide range of capacities (in tons). This section is used to mold PTFE powder into billets or custom shapes before further processing.

The molding section is featured with:

- Mold designs for both billets and custom preforms

- Controlled environment to prevent contamination

- Compression Molding is used for solid billets, sheets, rods, tubes, and blocks. This stage lays the foundation for high-density, uniform PTFE components used across industries

Key Equipment:

- Hydraulic presses

- Mold dies of various dimensions

- Powder loading hoppers with anti-contamination features

PTFE MOLDED UNSINTERED TUBES

FILLED PTFE MOLDED UNSINTERED TUBES

PTFE (Polytetrafluoroethylene) is a high-performance polymer known for its exceptional properties like non-stickiness, chemical inertness, and high thermal stability. Unlike most thermoplastics, PTFE cannot be injection molded or conventionally melt extruded due to its high viscosity and tendency to fracture when subjected to shear stress above its melting point (approximately 327-340°C).

Therefore, a unique processing technique called sintering is used to produce solid PTFE components from powder. Sintering involves heating the PTFE preform (compacted powder) above its melting point to cause the particles to coalesce and fuse, forming a solid, dimensionally stable part with reduced voids and enhanced strength.

- 1.Pre-forming or Cold Compaction: PTFE powder is cold-pressed into a desired shape using a mold and hydraulic press at room temperature, forming a "green" preform.

- 2.Drying and Degassing (if needed): If the PTFE powder contains additives or lubricants, or if trapped air needs to be released, a drying or degassing step at a lower temperature may be included before the main sintering process.

- 3.Controlled Heating (Ramp-up): The preform is then gradually heated in an oven to a temperature above the PTFE melting point, typically within the range of 360-380°C. Slow heating rates (e.g., 1.5-3°C/minute) are essential to prevent thermal stress and cracking, especially for large or thick parts.

- 4.Sintering (Soak Time): The material is held at the peak sintering temperature for a specific duration, typically 1-5 hours, depending on the thickness of the part and oven size. This holding time allows for the complete fusion and coalescence of the PTFE particles, eliminating voids and maximizing properties.

- 5.Controlled Cooling: After the soak time, the temperature is gradually decreased in a controlled manner to avoid inducing stresses and potential cracking. Cooling rates can range from slow annealing (e.g., 1-2°C/minute) to faster cooling processes (e.g., rapid quenching in air or water), depending on the desired mechanical properties and dimensional stability requirements. Slow cooling promotes crystallization and annealing, which helps relieve residual stresses.

- Initial Ramp-up (controlled heating): A gradual incline from room temperature to the peak sintering temperature (360-380°C).

- Soak (constant temperature): A horizontal line at the peak sintering temperature for a specified duration (1-5 hours).

- Controlled Cooling (gradual cooling): A gradual decline from the peak sintering temperature to room temperature.

While the exact profile can vary based on factors like part size, resin type, and desired properties, a general representation of a PTFE sintering cycle graph would look like this:

[Insert a graph with Temperature (°C) on the Y-axis and Time (Hours or Minutes) on the X-axis, showing the following phases]:

- PTFE melts around 327-340°C, becoming a transparent gel above this point.

- Over-sintering (too high temperature or too long soak time) can lead to material degradation.

- Rapid cooling can cause internal stresses and cracking.

- Slow cooling helps achieve optimal crystallization and minimize dimensional changes.

- The specific shape, size, and type of PTFE (virgin or filled) will impact the ideal sintering cycle parameters.

Important considerations:

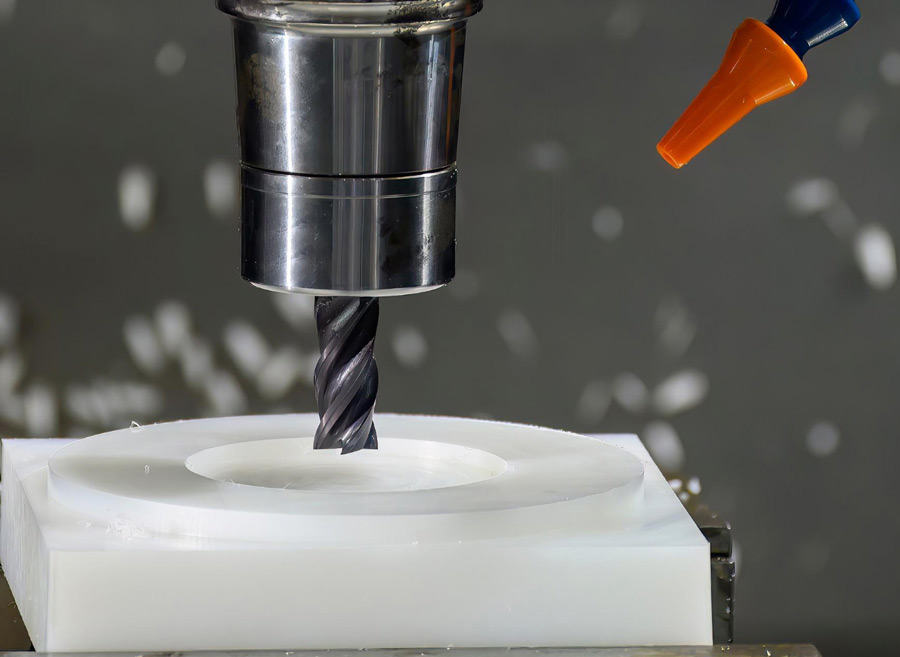

Post-sintering, billets are transferred to our machining section, where they are shaped into final products such as bushes, seals, rings, and gaskets, bushings and machined parts.

Our conventional lathe and CNC Machining Division is equipped for precision turning, drilling, and custom part shaping. We specialize in the conversion of sintered billets into high-accuracy components.

Key Features & Capabilities:

- High-precision CNC lathes

- Tolerances maintained as per customer drawings and international standards

- Experienced machinists for prototype and bulk production

- Tolerances up to ±0.1 mm

- Custom tooling for complex geometries

- Common Operations:

- Internal/external threading

- Facing, boring, slotting

- Grooving and profiling

- Skiving machines capable of thin sheets from sintered billets

- Sheet thickness ranging from microns to several millimeters

- Cleanroom conditions for high-purity and food-grade applications

- Optional backing as per client requirements

We maintain an in-house PTFE skiving unit for manufacturing sheets and tapes:

The Skiving Unit produces thin PTFE Sheets and tapes with consistent thickness and surface finish.

Quality Control and Inspection Facilities

- Dimensional inspection using digital gauges and Vernier's

- Surface finish and thickness verification for skived products

- Compliance with ASTM and ISO standards

Quality is integrated at every step with our in-house inspection facilities:

Quality control in a machine shop ensures manufactured parts meet strict design specifications by implementing a system of checks at various stages, including raw material inspection, in-process monitoring, and final product validation. Key aspects involve precise measurement with tools like calipers, height gauges, plug gauges, and CMMs, alongside quality management systems (QMS) and software for real-time data, process optimization, and traceability. Effective machine shop quality control relies on trained personnel, regular equipment maintenance, and a commitment to continuous improvement to achieve high-quality, consistent, and reliable finished components.

Key Stages of Quality Control:

Raw Material Inspection: Verifies that the incoming raw materials meet the required quality and property specifications before they enter the production process.

First Article Inspection (FAI): Involves a thorough check of the very first part produced after a setup to ensure it meets all design and quality standards, identifying any issues early.

In-Process Inspection: Checks critical dimensions, tolerances, and surface finishes at various stages of the machining process, allowing for real-time adjustments.

Final Inspection: A comprehensive evaluation of the fully machined parts to confirm they meet all quality standards and specifications before they are approved for use or shipment.

Tools and Technologies:

Precision Measuring Instruments: Tools such as calipers, height gauges, and various go/no-go gauges (plug and ring gauges) are used to measure dimensions and ensure adherence to tolerances.

Quality Management : Streamlines quality processes, provides real-time monitoring, automates inspections, and generates detailed reports for accountability and continuous improvement.

Essential Practices:

Equipment Maintenance: Regular cleaning, lubrication, and calibration of machinery ensure consistent, accurate results and reduce the likelihood of defects.

Personnel Training: Empowers all staff to identify, address, and contribute to the continuous improvement of quality processes.

Continuous Improvement: A commitment to regularly updating manufacturing processes based on production data, daily audits, and customer feedback to enhance efficiency and quality.

Documentation and Traceability: Maintaining comprehensive records for each part ensures accountability, facilitates quality audits, and provides a complete history of the production process

Quality assurance is integrated at every production stage. Our Inspection Division is staffed with trained quality controllers and equipped with modern measuring instruments.

- Profile projector

- Vernier calipers, micrometers, height gauges

- Digital thickness gauges

- Dial bore gauges

Instruments Available:

- First Article Inspection (FAI)

- In-process inspection during CNC operations

- Final dimensional and surface finish checks

Inspection Protocols:

Packaging is done with utmost care to ensure product integrity during transit. We offer custom packaging solutions based on client and export requirements.

- Clean room packaging for critical applications

- Use of anti-static bags, wooden crates, corrugated boxes

Features:

- Recyclable materials wherever applicable

Eco-conscious Approach:

Our logistics and dispatch division is responsible for timely and secure delivery of products across domestic and international markets.

- Streamlined inventory, labeling, and logistics handling

- Inventory-controlled dispatch bays

- Tie-ups with trusted logistics and courier partners

- Export documentation and custom clearance support

Facilities:

- Logistic follow-ups and client communication

Dispatch Monitoring:

From standard sheets to custom components, we're ready to deliver quality you can rely on.

Contact Us