FILLED GRADES OF PTFE:

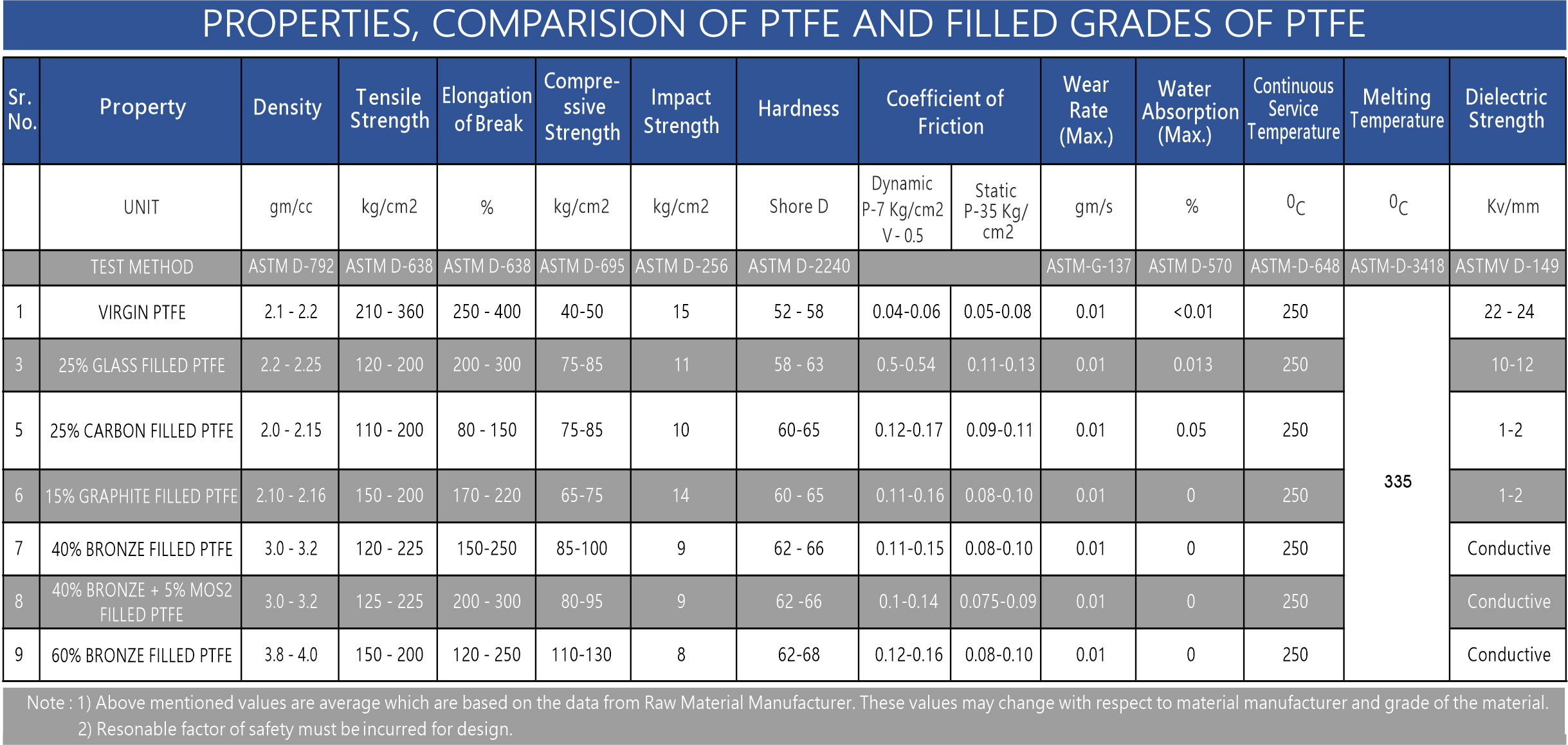

Filled PTFE offers enhanced properties compared to virgin PTFE, such as improved wear resistance, higher compressive strength, and better thermal conductivity, depending on the filler used. Common fillers include carbon, glass, graphite, and bronze. These modifications lead to a wider range of applications, particularly in demanding environments.

GENERAL ADVANTAGES OF FILLED PTFE:

- Enhanced Wear Resistance: Fillers like carbon and graphite significantly improve wear resistance, making filled PTFE suitable for dynamic sealing and high-speed applications.

- Increased Compressive Strength: Bronze and carbon fillers, in particular, enhance the compressive strength of PTFE, allowing it to withstand higher loads and pressures.

- Improved Thermal and Electrical Conductivity: Bronze and certain other metal-based fillers can increase the thermal and electrical conductivity of PTFE, which is beneficial in specific applications.

- Reduced Cold Flow and Creep: Fillers like bronze and glass can minimize cold flow and creep, improving the dimensional stability of PTFE components under load.

- Tailored Properties: The choice of filler allows for customization of PTFE properties to meet specific application requirements.

| SL. | GRADE | PROPERTIES | APPLICATIONS |

| 1. | Glass Fiber Filled PTFE: | Increased compressive strength, improved wear resistance, reduced creep, better dimensional stability, and enhanced thermal and electrical properties. Improved hardness, lower thermal expansion, lower deformation under load, and increased wear resistance. |

Piston rings, shaft bearings, valve seats, shaft seals, gaskets, insulation in high-temperature environments, and parts for pumps and fluid handling systems. |

| 2. | Carbon Fiber Filled PTFE: | Higher compressive strength and wear resistance, low permeability, improved thermal conductivity, and better resistance to creep compared to glass-filled PTFE. Excellent compressive strength, wear and chemical resistance, good thermal conductivity, and low permeability. |

Bearings, piston rings, rider rings, and seals in high-stress and temperature automotive and aerospace applications. |

| 3. | Carbon/Graphite Filled PTFE: | Improved wear resistance, enhanced thermal and electrical conductivity, and good sliding characteristics. Low coefficient of friction, excellent wear properties, and high load-carrying capability. |

Bearings, piston rings, seals, gaskets, and filter housings, especially in applications requiring electrical conductivity or high thermal conductivity. |

| 4. | Bronze Filled PTFE: | Increased hardness, improved wear resistance, better thermal conductivity, and reduced creep and cold flow. Increased compressive strength, enhanced thermal and electrical conductivity, and improved dimensional stability. |

Bearings, bushings, gears, seals, gaskets, and components for hydraulic systems. |

| 5. | Stainless Steel Filled PTFE: | Excellent strength and stability under extreme loads and temperatures, good wear resistance, and improved chemical resistance. | Applications: Bearings, valve seats, and seals, particularly in steam environments and high-temperature liquid applications. |

| 6. | Molybdenum Disulfide (MoS2) Filled PTFE: | Increased surface hardness and stiffness, reduced coefficient of friction and wear. | Dynamic seals and parts in dry gas or vacuum environments, where self-lubrication is critical. |

| 7. | Glass Fiber & MOS2 Filled PTFE: | MoS2 as one of the best known dry lubricants can improve surface strength and lower friction and wear rate coefficient, while the glass fibers provide structural strengthening. The glass does not get influenced by chemical or electrical specifications, nor will the MOS2. | PTFE bushings - 15% Glass Filled & 5% MoS2 are suitable for seals in hydraulic applications with low to middle pressure values. |

APPLICATIONS OF FILLED GRADES OF PTFE

Filled PTFE, which is PTFE (Polytetrafluoroethylene) combined with various fillers, offers enhanced properties and is used in a wide range of applications. Common fillers include glass, carbon, bronze, and stainless steel, each imparting specific characteristics to the PTFE. These filled PTFE materials find use in industries like automotive, aerospace, chemical processing, and electrical engineering, due to their improved wear resistance, mechanical strength, thermal conductivity, and electrical properties.

Specific Applications:

- Automotive: Filled PTFE, particularly carbon-filled PTFE, is used in seals, gaskets, and bearings where high wear resistance and performance under stress and temperature are crucial.

- Aerospace: Glass-filled PTFE is utilized in aerospace parts like bearings and seals due to its low friction, high strength, and resistance to temperature variations.

- Chemical Processing: PTFE with various fillers, including calcium fluoride for specific chemical resistance, is employed in valves, pumps, and piping to handle corrosive chemicals.

- Electrical and Electronics: Filled PTFE, especially carbon-filled, provides electrical conductivity and static dissipation, making it suitable for conductive gaskets, anti-static parts, and insulation.

- Industrial Equipment: Bronze-filled PTFE is used in bearings, bushings, and wear strips in machinery where low friction and high wear resistance are needed.

- Food Processing: Glass-filled PTFE is used in conveyor systems and machinery where a clean and smooth surface is required.

- Pharmaceuticals: Glass-filled PTFE can be used in parts requiring non-stick surfaces and easy cleaning in pharmaceutical applications.

- Medical: PTFE coatings enhance the functionality and longevity of medical devices like catheters, surgical tools, and implants.

- Cookware: PTFE is well-known for its non-stick properties in cookware.

Types of Fillers and Their Effects:

- Glass Fiber: Increases compressive strength, wear resistance, and reduces cold flow, making it suitable for valve seats, bearings, and pump parts.

- Carbon Fiber/Powder: Enhances thermal and electrical conductivity, making it suitable for applications needing static dissipation and thermal management.

- Bronze: Improves mechanical strength, wear resistance, and load-bearing capacity, making it useful for bearings, seals, and slide plates.

- Stainless Steel: Provides high-temperature resistance and increased strength, suitable for applications involving steam and hot liquids.

- Calcium Fluoride: Offers resistance to chemicals that attack glass, such as hydrofluoric acid and strong alkalis.

PTFE Grades and Fillers

| Grade / Filler | Typical Filler % | Color | Key Applications | Enhanced Properties | Chemical Resistance Notes |

|---|---|---|---|---|---|

| Virgin PTFE | 0 | Milky White | Food, medical, gaskets, insulation | Max chemical resistance | Excellent except alkali/flourine |

| Glass-Filled PTFE | 15–25 | Off White | Bearings, gaskets, valve seats | Wear, compressive strength | Very high, avoid strong alkalis |

| Carbon-Filled PTFE | 10–35 | Black | Anti-static, bushes, dry bearings | Conductivity, wear | High, generally safe |

| Graphite-Filled PTFE | ~15 | Grey | Seals, bearings, piston rings | Low friction, wear | Very high, inert |

| Bronze-Filled PTFE | 40–60 | Brown | Hydraulic, high load bearings | Thermal conductivity, load cap | Lower, avoid strong acids |

| Glass + MoS2-Filled PTFE | 5 + 10 | Bluish Grey | Valve seats, wear pads | Lubricity, wear | High, but test for specific media |

| Bronze + MoS2-Filled PTFE | 55 + 5 | Blackish Brown | Heavy-duty wear parts | Load, lubricity | Lower, not for strong acids |

| Molybdenum Disulfide (MoS2) PTFE | 0.1–15 | Dark/Light Grey | Wear strips, dry lubricated bearings | Lubricity, hardness | Very high, avoid oxidizers |

| Stainless Steel-Filled PTFE | 5–10 (typical 50) | Grey | High wear/abrasion rings | Load, abrasion | Specific, generally stable |

| Aluminum Oxide-Filled PTFE | 5–10 | Cream | High abrasion environments | Hardness, wear | High |

| Calcium Fluoride (CaF2) PTFE | 5–10 | Cream | Cryogenic parts | Low friction at low temps | Good, test for compatibility |

| Peek-Filled PTFE | 10–30 | Beige | High temp, seals | Strength, heat stability | Good |

| Mica-Filled PTFE | 5–10 | Cream | Abrasives, electrical | Hardness, insulation | High |

| Pigmented PTFE (various) | Variable | Red, Blue, etc. | Custom, color-coded | Appearance | Similar to parent PTFE |

| Boron Nitride-Filled PTFE | ~10 | Cream | High-temp, electronics | Lubricity, thermal | High |

From standard sheets to custom components, we're ready to deliver quality you can rely on.

Contact Us