Precision Machined PTFE Guide Rings for Hydraulic and Pneumatic Systems – By National Fluoromers

| Property | Value |

|---|---|

| Material | Virgin PTFE, Glass-filled PTFE, Bronze-filled PTFE |

| Standard sizes | Ø10 mm to Ø500 mm (custom on request) |

| Thickness / width | 1 mm to 25 mm |

| Operating temperature | –200°C to +260°C |

| Color | White, green, brown, blue, or as specified |

| Tolerance | Customer-defined |

Whether you need standard sizes or custom-made profiles, our PTFE Guide Rings are trusted across industries for their unmatched performance under extreme pressure, temperature, and chemical exposure.

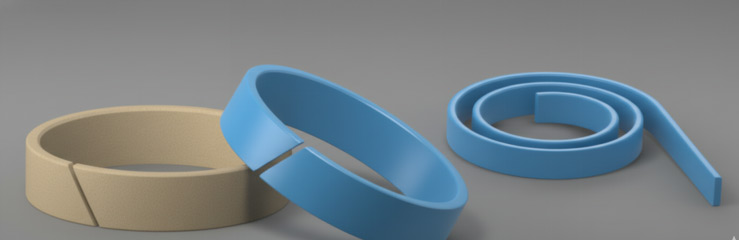

A PTFE Guide Rings (also called a wear ring or bearing ring) is a non-metallic ring placed on pistons or rods within cylinders to guide motion and absorb lateral forces, while protecting seals from excessive wear. PTFE’s low coefficient of friction, self-lubricating nature, and chemical inertness make it a perfect material for smooth, controlled motion in demanding environments.

PTFE Guide Rings are often preferred over metallic ones due to their ability to reduce scoring, vibration, and misalignment.

- Low friction & self-lubricating: No need for external lubrication.

- High wear resistance: Extended life under dynamic load conditions.

- Chemically inert: Resists oils, fuels, hydraulic fluids, and solvents.

- No stick-slip: Delivers smooth and silent linear motion.

- Wide temperature range: Performs from –200°C to +260°C.

- Easy installation: Supplied in split or solid form.

- Prevents scoring and scratching of cylinder walls

- Reduces downtime by protecting main sealing elements

- Suitable for reciprocating, rotating, or oscillating motion

- Improves machine accuracy and repeatability

- Works in dry, wet, or chemically aggressive environments

- Custom profiles and materials available for specific applications

- Hydraulic and pneumatic cylinders

- Injection molding machines

- Mobile equipment (construction, mining, lifting)

- Presses and servo-actuators

- Chemical pumps and dosing units

- Offshore and marine systems

- Robotics and automation systems

- Hydraulic & pneumatic equipment

- Construction & earthmoving machinery

- Food & beverage processing

- Oil & gas

- Marine & shipbuilding

- Industrial automation

- Plastic injection & blow molding

- Aerospace & defense

- Precision-machined Guide Rings to exact dimensions

- Wide material options for heat, pressure, and chemical resistance

- Split and continuous designs available

- Rapid prototyping and low MOQ for custom projects

- Global delivery and OEM packaging support

- Split rings, solid rings, or spiral cut for easy installation

- Delivered in kits or individually packed

- Bulk packaging or custom branding available

- Ready-to-install on shafts, rods, or pistons

Send us your dimensions or application specs – we will engineer the right Guide Rings for your needs.

Contact Us