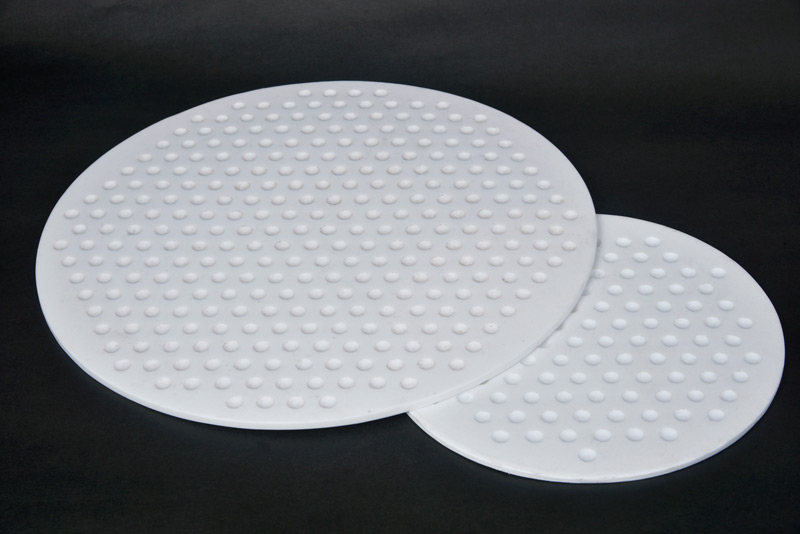

Structural Drade PTFE Dimpled Sheets & Bridge Bearing Pads – Manufactured By National Fluoromers

Our precision-molded PTFE Dimpled Sheetss are trusted by civil engineers and infrastructure contractors across india and globally for their strength, durability, and low maintenance requirements.

| Property | Value |

|---|---|

| Material | Virgin or filled PTFE |

| Surface design | Precision-molded dimple pattern |

| Thickness | 3 mm to 8 mm (or custom) |

| Diameter | 1000 mm |

| Sheet size | Standard: 100 mm up to 1000 mm / custom |

| Coefficient of friction | 0.04 – 0.06 |

| Operating temperature | –200°C to +260°C |

| STD | AS PER IRC 83 |

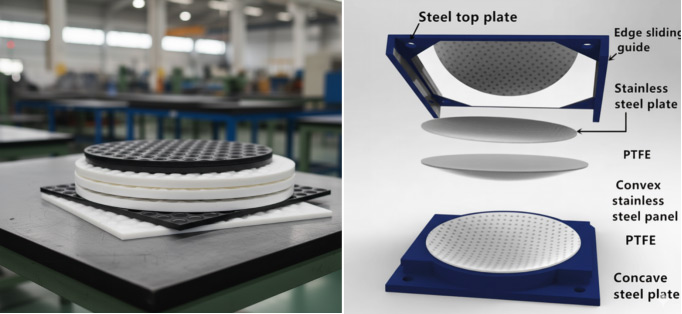

There are no off-the-shelf convex or concave PTFE sheets for bridge bearings, as these components are custom-made as part of a specialized pot bearing assembly. In this system, the flat, low-friction PTFE sheet is recessed into a piston that fits inside a pot, while the curved surface is a mirror-polished stainless steel plate. This configuration allows for rotational movement that is not possible with simpler flat sliding bearings. The convex and concave geometry refers to the pot and its corresponding piston, not the flat PTFE sheet itself.

Convex PTFE sheets are specialized products used in bridge bearings to facilitate smooth movement and accommodate structural shifts. These sheets leverage PTFE’s extremely low coefficient of friction, making them ideal for high-load, low-speed sliding applications in civil infrastructure such as bridges.

Function and Application

- Convex PTFE sheets are typically paired with a matching concave stainless steel mating plate within a sliding bearing assembly.

- The convex (curved outward) geometry is designed to allow for both horizontal translation (sliding motion) and rotational movement (accommodating changes in bridge alignment due to load, expansion, or seismic activity).

- PTFE surfaces are usually bonded to structural backing plates and sometimes chemically etched on one side to ensure strong adhesion to the metal substrate.

Material Properties

- PTFE (Polytetrafluoroethylene) is chosen due to its excellent chemical inertness, low friction (μμ as low as 0.03 to 0.12 with proper lubrication), and ability to handle high pressures and temperature extremes frequently encountered in bridge environments.

- Filled grades of PTFE, such as PTFE with glass fiber or bronze, are often used to increase wear resistance and load-carrying capacity.

Key Benefits

- Minimal maintenance due to self-lubrication.

- Accommodate vertical, horizontal, and rotational movements, which is critical for modern bridge engineering.

- Extended lifespan owing to PTFE’s resistance to aging, UV, water, and most chemicals.

Typical Construction

- The PTFE layer is generally 2–5 mm thick, bonded to a steel backing.

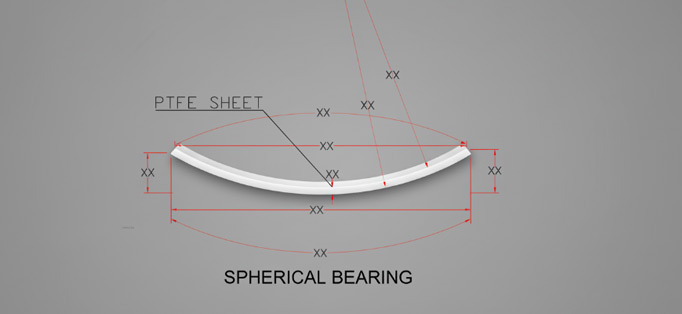

- The convex lower plate (with PTFE) slides against a matching concave stainless steel upper plate, creating a spherical bearing system.

| Feature | Details |

|---|---|

| Geometry | Convex (curved) PTFE surface |

| Material | Virgin or filled PTFE, steel backing |

| Friction Coefficient | 0.03–0.12 (lubricated) |

| Common Thickness | 2–5 mm |

| Main Function | Bearing rotation & translation in bridges |

Use in Bridge Bearings

- Convex PTFE sheets are critical where bridges demand multi-directional movement and alignment adjustment, especially in large civil projects like flyovers, metro corridors, and railway overpasses.

- For further technical details—such as sample specifications, data sheets, and sourcing information—reviewing the product standards (EN 1337-2, AASHTO) and consulting suppliers specializing in PTFE bridge bearing solutions is recommended.

A PTFE Dimpled Sheets is a specially molded PTFEsheet with a surface textured with uniformly spaced dimples. These dimples minimize contact area while ensuring high load transfer capability. The reduced friction makes them ideal as sliding components in bridge bearings, expansion joints, and other structural support systems.

PTFE(polytetrafluoroethylene) dimpled sheets, also known as PTFEbearing pads, are specialized sheets used in various engineering and construction applications, particularly in bridge and structural engineering. They feature a dimpled surface that facilitates smooth, low-friction movement between two surfaces, often acting as a self-lubricating system. These sheets are known for their chemical inertness, temperature resistance, and ability to withstand high loads.

Also known as PTFE Bridge Bearing Pads, these components are typically bonded with elastomeric or stainless-steel backing to create high-performance sliding bearings.

PTFE(polytetrafluoroethylene) Bridge Bearing Pads, also known as structural bearings, are crucial components in bridge construction and other structures requiring movement accommodation. These pads, often made with a PTFEsheet bonded to an elastomeric bearing, allow for smooth sliding and rotation under load, accommodating thermal expansion, contraction, and other movements. Their low friction coefficient and self-lubricating properties make them highly effective for these applications.

- Elastomeric bearings with PTFE sliding sheet: These bearings combine the load-bearing capacity of elastomeric pads with the sliding capabilities of PTFE.

- Rectangular and round PTFE bearing pads: Depending on the bridge design, either rectangular or round PTFE bearing pads are used to accommodate different load and movement requirements.

Standards used for PTFE bridge bearings include international standards like EN 1337 for Europe, AASHTO and BS: 5400 globally, and the Indian standard IRC: 83 (Part II) for POT-PTFE bearings. Specific material standards for PTFE often reference BS:3784 or other international specifications for bridge bearing quality.

- EN 1337 (Europe): This is a key European standard that defines the requirements and specifications for structural bearings, including those made with PTFE.

- AASHTO: The American Association of State Highway and Transportation Officials provides standards that are relevant to sliding bearings used in bridges.

- BS:5400 (British Standard): This standard for bridges also covers specifications for both POT and sliding bearings.

- IRC:83 (Part II): The Indian Road Congress's code for POT-PTFE bearings.

- RDSO (Research Designs & Standards Organisation): The standards developed by RDSO govern the quality assurance for pot-PTFE bearings in India.

- Material Quality: PTFE used in bridge bearings is often described as "bridge bearing quality" or "PTFE in bridge bearing quality" to indicate it meets high specifications for mechanical and tribological properties, as outlined in standards like EN 1337.

- BS:3784: For basic PTFE material properties, standards like BS:3784 are used for unfilled PTFE.

Several types of bridge bearings incorporate Polytetrafluoroethylene (PTFE) to reduce the coefficient of friction and facilitate smooth, controlled movement in structures. These specialized bearings are designed to accommodate the movements and rotations of bridge decks caused by temperature changes, traffic loads, and other forces.

- Pot-PTFE Bearings: Pot-PTFE bearings are robust, high-capacity bearings used for large-span bridges.

- Structure: They consist of a steel "pot" enclosing an elastomeric pad. A piston sits inside the pot on the pad. A PTFE layer is integrated onto the piston's top to create a low-friction sliding surface.

- Mechanism: The elastomer pad acts like a confined fluid, distributing the vertical load evenly. Horizontal movement is accommodated by the sliding of the PTFE surface against a polished stainless steel plate.

- Configurations: Pot-PTFE bearings can be manufactured in several configurations to suit specific design needs, including:

- Fixed: Allows for rotation only.

- Free: Allows for sliding and rotation in all directions.

- Guided: Allows for sliding and rotation in a single, predetermined direction.

- PTFE Sliding Elastomeric Bearings: These bearings combine the rotational ability of a laminated elastomeric bearing with the low-friction sliding properties of PTFE.

- Structure: A layer of PTFE is bonded to the top surface of a standard laminated elastomeric bearing pad. The bearing pad is made of reinforced natural or chloroprene rubber.

- Mechanism: The elastomer pad handles vertical loads and rotations. For large horizontal displacements, the PTFE top surface slides against a polished stainless steel plate.

- Design Features:

- The PTFE surface often has small indentations, or "dimples," that contain a lubricant to further reduce friction.

- Available in various shapes, such as rectangular and round.

- Guided versions use side steel plates or guide pins to control the direction of movement.

- Spherical-PTFE Bearings: Spherical bearings are designed for structures that require significant rotation in any direction, such as curved or skewed bridges.

- Structure: A convex steel plate slides against a concave steel plate, with a low-friction PTFE layer recessed into the concave plate. A polished stainless steel surface on the convex plate completes the sliding mechanism.

- Mechanism: This configuration allows for multi-directional rotation and movement. A guide, such as a pin or ring, can be added to the bearing to restrict sliding to a single direction.

- Configurations: Similar to pot bearings, spherical-PTFE bearings come in fixed, guided, and free-sliding types.

- PTFE Slide Plates: These are the simplest type of PTFE bearings and are typically used for smaller structures or applications with lower loads and rotations.

- Structure: The bearing consists of a flat PTFE plate and a flat stainless steel plate, with each bonded or welded to a separate structural steel plate.

- Mechanism: The stainless steel plate slides directly against the PTFE plate to accommodate movement.

- Applications: Suitable for applications like pipe supports and expansion joints in concrete slabs, where a continuous sliding surface is needed.

- Limitations: Less suited for high-rotation applications than pot or spherical bearings, though an elastomeric layer can be added to compensate for small rotations.

- Bridges: PTFE bearing pads are commonly used in bridges to accommodate thermal expansion, contraction, and other movements.

- Buildings: They can also be used in buildings to support beams and girders, allowing for movement and reducing stress.

- Pipelines: PTFE bearing pads can be used in pipelines to accommodate movement and reduce stress on the pipeline.

- Other structures: They can also be used in other structures where movement and load transfer are required.

- Textured dimpled surface: Reduces static and dynamic friction.

- Excellent load bearing: Handles compressive loads in static and moving structures.

- Weather & UV resistance: Performs reliably in outdoor and exposed conditions.

- High thermal stability: Operates from –200°C to +260°C.

- No creep or cold flow: Excellent dimensional stability under prolonged stress.

- Allows smooth structural movement in bridges and buildings

- Reduces stress on joints due to thermal expansion

- Self-lubricating, requiring no additional maintenance

- Corrosion resistant even in marine or coastal environments

- Custom-engineered for specific load and movement conditions

- Expansion joints in bridges and flyovers

- Sliding elements in large-span buildings

- Load distribution in metro and rail infrastructure

- Earthquake-resistant structural pads

- Machinery base supports for heavy industries

- Civil & structural engineering

- Infrastructure & highways

- Construction & real estate

- Railways & metros

- Marine & offshore projects

- Heavy equipment foundation systems

- Precision-engineered dimple design for optimal performance

- Manufacturing compliance with global infrastructure standards

- Extensive supply experience for public and private sector projects

- Dimpled PTFEsheets in custom dimensions and thicknesses

Our engineers are here to support your next infrastructure project with high-performance solutions.

Contact Us