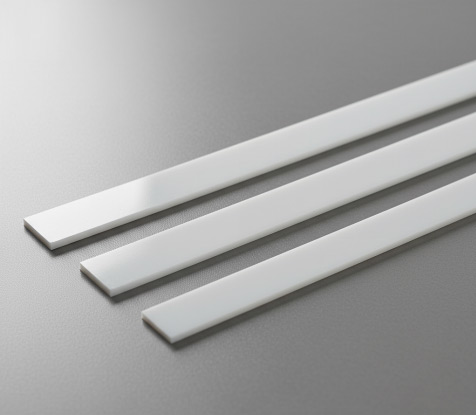

High Quality PTFE Strips Manufactured & Supplied By National Fluoromers

| Property | Value |

|---|---|

| Material | Virgin or filled PTFE |

| Width | From 3 mm up to 300 mm (custom) |

| Thickness range | 0.1 mm to 5 mm |

| Length | Cut lengths or continuous rolls |

| Temperature range | –200°C to +260°C |

| Surface | Smooth or textured (optional) |

| Color | White (standard), other colors optional |

Available in a wide range of thicknesses and widths, our PTFE Strips can be customized to meet specific operational requirements, making them ideal for oems, maintenance engineers, and industries looking for reliable performance and precision.

A PTFE Strips is a narrow, flat-cut sheet made from virgin or filled PTFEmaterial, designed for applications where precision, flexibility, and resistance to extreme environments are critical. These strips can be supplied in coils, cut lengths, or die-cut forms based on the client's needs.

Their non-stick surface, low friction, and excellent mechanical properties make them a go-to solution for gasketing, insulation, and anti-friction padding in industries across the spectrum.

- Narrow widths for tight applications: Perfect for grooves, channels, and small enclosures.

- High chemical inertness: Unaffected by most industrial solvents, acids, and alkalis.

- Broad thermal range: Performs reliably from –200°C to +260°C.

- Smooth, non-adhesive surface: Prevents sticking, buildup, and contamination.

- Excellent dielectric properties: Ideal for electrical insulation.

- Easy to handle, install, and fabricate

- Custom-cut lengths and thicknesses available

- No degradation in harsh, corrosive, or high-temperature settings

- Low friction and excellent wear resistance

- Non-toxic and FDA-compliant options available

- Gasketing and sealing: Ideal for flanges, tanks, and ducts in corrosive environments.

- Insulation and spacers: Used in high-voltage equipment and electronic components.

- Wear strips and guides: Provides low-friction movement in mechanical assemblies.

- Food & pharmaceutical: Non-toxic sealing solutions for packaging and processing machinery.

- Slide bearing surfaces: In conveyors and structural movement systems.

- Chemical processing

- Electrical & electronics

- Food & beverage

- Mechanical engineering

- Pharmaceuticals

- Aerospace & automotive

- State-of-the-art manufacturing and CNC precision machining

- Flexible supply options for bulk, OEM, or custom applications

- Quick turnaround on urgent and tailored orders

- Export-ready with international shipping support

- Technical advisory to help you choose the right grade and configuration

- Continuous PTFE Strips on rolls

- Custom-cut sizes and adhesive applicable strips

- Virgin and filled PTFE variants (glass, carbon, bronze, etc.)

- FDA-compliant grades for food and medical applications

Our technical experts are ready to help you find the ideal strip configuration for your project.

Contact Us