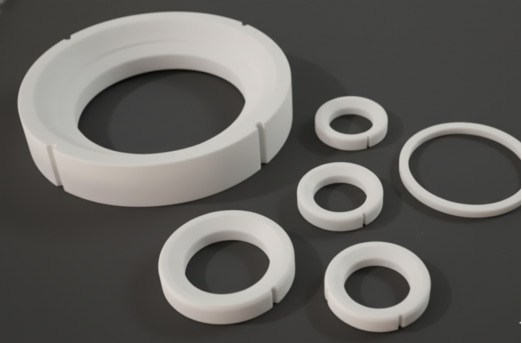

High Performance PTFE Ball Valve Seat Rings – By National Fluoromers

| Property | Value |

|---|---|

| Material | Virgin PTFE, Glass-filled PTFE, Carbon PTFE |

| Outer diameter (OD) | 10 mm to 500 mm (custom on request) |

| Inner diameter (ID) | As per ball valve size |

| Thickness | 1 mm to 25 mm |

| Operating temperature | –200°C to +260°C |

| Seat design | Round, profile cut, fire-safe, split ring |

Used extensively in chemical, oil & gas, pharmaceutical, and food-grade systems, our PTFE seat rings provide reliable shut-off with minimal torque and wear.

A PTFE Ball Valve Seat Rings is a precision-machined sealing component installed within a ball valve to ensure tight shut-off and facilitate smooth ball rotation. It provides a low-friction, leak-proof interface between the ball and the valve body, even under high pressure, aggressive media, or high temperatures.

Due to PTFE’s self-lubricating and chemically inert properties, it is widely preferred for ball valve seats in high-purity or corrosive fluid systems.

- Superior chemical compatibility: Resistant to most aggressive acids, alkalis, and solvents.

- Low friction operation: Enables smooth rotation of valve ball with minimal torque.

- Thermal stability: Performs consistently from –200°C to +260°C.

- Leak-proof performance: Maintains seal integrity over long cycles.

- FDA-grade available: Suitable for food, water, and pharmaceutical valves.

- Custom designs: Available in full-port, reduced-port, or V-notch valve configurations.

- Eliminates leakage and minimizes wear

- No need for lubrication or frequent maintenance

- Prolongs valve life in abrasive or corrosive conditions

- Custom-fit to valve design with precision tolerances

- Non-stick surface resists fouling and buildup

- Compatible with soft-seated and fire-safe valve designs

- On-off and control valves in chemical processing

- Steam and gas ball valves

- Corrosive media valves in pharmaceuticals and biotech

- Food-grade valves in beverage and dairy industries

- Water treatment and desalination plants

- Marine and offshore ball valves

- Chemicals & petrochemicals

- Food & beverage

- Pharmaceuticals & biotech

- Water & wastewater

- Oil & gas

- Marine & power plants

- Pulp & paper

- General industrial process equipment

- Expert CNC machining for perfect sealing and alignment

- Custom-made rings based on valve brand, design, or drawing

- Choice of virgin or filled PTFE grades for specific conditions

- High-volume production capabilities with tight QA control

- Responsive customer support and fast dispatch

- Supplied as individual seat rings or complete valve seat sets

- Available with surface finish options (smooth, grooved, mirror)

- Supplied in cleanroom-ready packaging on request

- Bulk or OEM supply supported

Send us your valve specifications or samples – we will provide a perfect-fit PTFE seat solution.

Contact Us